- MERTERT

- + 352 74 83 78

- trek@asc.lu

One-to-One by fizik is a revolutionary new program for designing, building, and delivering bespoke saddles for individuals using a rider’s unique biometric data and personal pressure profile, making customized support available to every cyclist.

Introducing One-to-One, a paradigm-shifting service that enables the creation of custom-tailored saddles based on a rider’s individual biometric data.

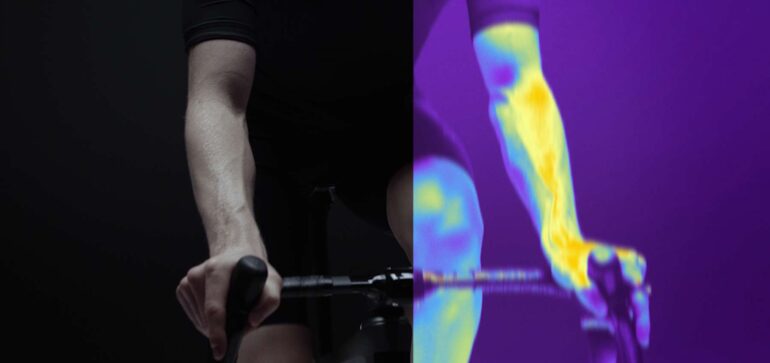

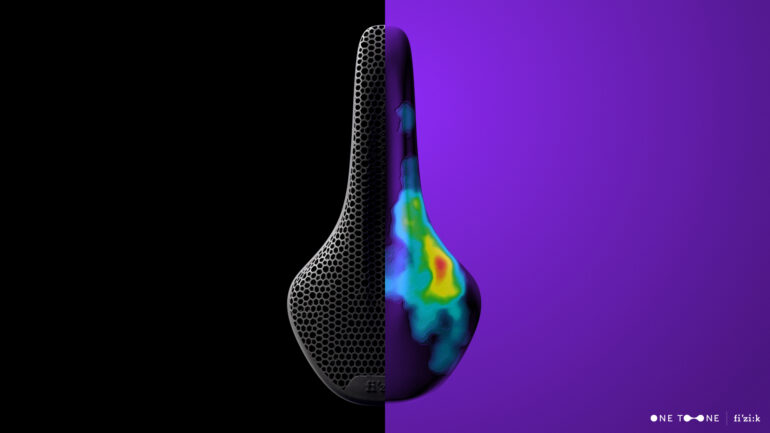

By recording the pressure a cyclist exerts on the saddle, captured dynamically while riding, we map out a unique pressure profile, using this data to produce a bespoke 3D-printed saddle padding that offers unparalleled improvements in both comfort and performance.

Taking the technology that powers our Adaptive line of 3D-printed saddles to the next level, One-to-One represents the pinnacle of personal, data-driven design and engineering, making customized support available to every cyclist.

Traditional saddles consist of foam padding with a given density across the entire sitting surface.

Different sizes fit different ischial bone widths, and different shapes suit specific riding postures (more upright vs sporty or aggressive), riding disciplines (gravel, MTB, endurance, TT, etc.), or provide specific functional benefits (channels, cut-outs, etc.).

Inserts made from various materials are available in certain saddles to provide functional comfort areas in specific spots.

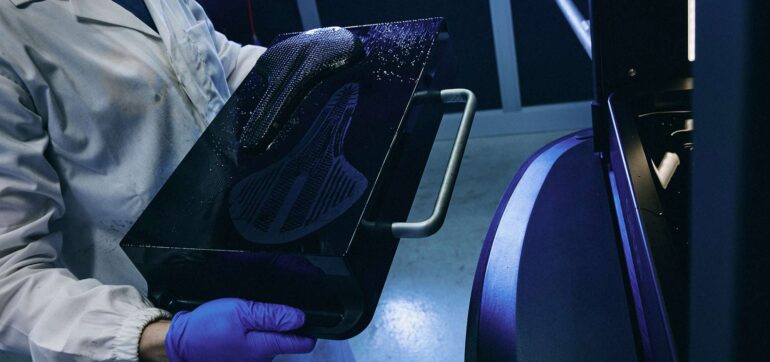

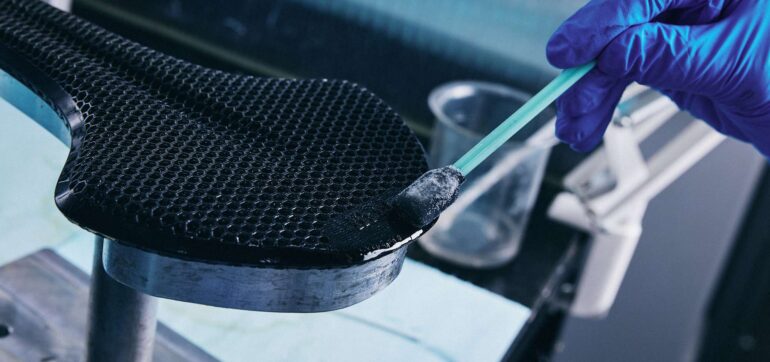

Recently, through the adoption of Carbon Digital Light Synthesis™ (Carbon DLS™), we introduced our Adaptive 3D line of saddles.

Carbon’s 3D printing technology allowed us to develop a new saddle without the constraints or limitations imposed by traditional production methods and materials: to design and manufacture multiple functional zones within the saddle, joined together progressively and seamlessly in the same padding.

Adaptive enabled the creation of seamless, distinct functional comfort zones within the same saddle padding, but that isn’t the only benefit of this additive manufacturing process.

It also makes it easier to manufacture one-off production parts, as opposed to traditional injection molding which requires a larger-scale commitment and entails high tooling costs.

Without the constraints of batch production imposed by injection molding methods, each 3Dprinted Adaptive saddle padding can be totally unique, which leads to the logical question: What if saddle padding was produced based on an individual rider’s specifications? And therein lies the true potential of Adaptive saddle technology.

With this as our goal, we spent the last three years researching, developing, testing, and confirming a process through which we could capture, interpret, and translate a rider’s personal pressure data into a 3D-printed structure—a saddle made just for you, based on you and your needs.

Just like a tailor must take your measurements to sew a custom suit, we also must attain the relevant information to create a custom saddle —and that means measuring pressure.

Pressure measurements include the force our bodies transfer to the saddle as well as how that force is distributed across the saddle’s surface. Of course, that pressure changes continuously while riding, as we pedal and shift riding positions, which makes it crucial to capture pressure measurements dynamically, while we are actually in motion.

Together with GebioMized, we have developed a Pressure Sensor Mat capable of measuring pressure at 64 points spread out across the saddle’s surface, relaying data in real time wirelessly via a built-inBluetooth Transmitter. As opposed to more traditional tools that aim to measure sitbone distance or sacrum angle, measuring pressure while riding reflects the real sitting position on the bike and allows us to identify the parameters that matter most, like indicators of stability on the saddle, peak pressure identifiers and hotspots as well as pelvic tilt. Pressure data from each measurement session is recorded while riding on the handlebar tops, hoods, and in the drop position for road and gravel, aero and basebar for TT and triathlon, and handlebar for MTB. Once processed, it is then cross-checked with a rider’s discipline and gender to ensure correct interpretation. fizik

The first step of a One-to-One measurement session is to match the rider with the ideal fizik saddle shape.

For this, we have developed a matching algorithm that takes into account all key parameters derived from initial data collection to determine the most suitable saddle shape for a given load type and riding style. The broadest selection of fizik saddles is available for customization.

Available in

140mm / 150mm

Available in

140mm / 150mm

Available in

140mm / 150mm

Available in

145mm / 155mm

Available in

135mm

Available in

135mm

Available in

140mm / 150mm

Available in

140mm / 150mm

Available in

140mm / 150mm

Available in

145mm / 155mm

Available in

135mm

Available in

135mm

Includes:

• Saddle fitting session

• Pressure mapping using Gebiomized technology

• Installation of your new saddle

Note:

To perform the saddle sizing, a prior bike fitting session is required.

No additional fee applies if the saddle sizing is done as part of a standard bike fit – in that case, only the saddle is charged.

Leave us your email and we’ll get back to you when our webshop is live :)